*Updated August 5, 2010

Special Projects & Facilities

MAI Office Building

MAI Office Building

A new office building is being renovated for employees of Morrell Agro Industries in Addis Ababa, in an effort to get all staff members together under one roof. The building is four floors, of which MAI is leasing the top two for company use.

Carpets, phone systems, and IT hardware were installed during the last week of May. A final inspection by the contractors was also completed. They released the building to allow the carpets to be laid.

MAI employees were able to move into the building as soon as these installations were completed, and it is a great advantage to the company to have everyone working together in one location.

Negotiations are underway with various offices and companies to lease the parts of the office building that MAI will not use. The ground floor and half of the first floor are still available for lease. MAI is hoping that those parts of the building will be used by companies that will complement MAI and their mission – companies that will integrate easily into the building’s atmosphere.

Alyssa Farm

Alyssa Farm

The beginning phases of design and preparation have begun for the construction of a seed cleaning facility and mechanic shop on the Alyssa farm. Both of these facilities will be housed in a single building, to save on construction and maintenance costs. This completed building will be 100 meters by 20 meters and 20 feet high. 75 meters of the building will be dedicated to the seed cleaning facility, and 25 meters will be dedicated to the equipment shop.

The materials used in building construction will be primarily steel. It is simple to clean, maintain, and manage. It will most likely be constructed without insulation, as it will not sustain much of a difference in regards to the heat factor in the building.

The seed cleaning facility equipment is currently being shipped from the United States to Ethiopia. MAI is working with a steel building manufacturing company in Ethiopia in order to acquire the building that will house the seed cleaning operation on the Alyssa farm.

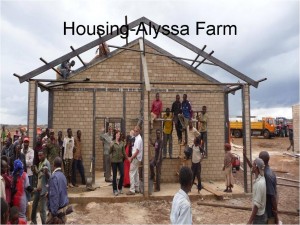

Several of the houses for the Alyssa farm property have been completed. Building materials, such as hydra-form blocks, windows, and doors, are being stockpiled for the future construction of the remaining houses, as well as a bunkhouse, on the farm. The poor road conditions to Beltu remain the biggest issue in getting building materials to the Alyssa farm in a timely and whole manner.

Grain Storage

Until a grain storage facility is constructed on the farm, there is a need for short-term storage options as grain is harvested. Phil Morrell has made available an 80 foot by 120 foot soft-sided super structure. MAI is working with the original manufacturing company, so that any broken or missing parts can be replaced or repaired as needed and in order to receive onsite technical support in Ethiopia. The structure will not arrive in time for use in the current harvest season that is underway, but it will be made use of in the future.

By the end of July and the beginning of August 2010, a means of grain storage will be needed on the Alyssa farm. MAI staff will try to obtain one-time use silo bags, which will store the grain as it is harvested. Ethiopian-style storage buildings can also be constructed on the property; they will then be available afterwards for other purposes on the farm.

In the case of a short-term emergency, the grain can be stockpiled in a huge pile on the ground outside, with tarps tied over the top of the piles. In the heavy rains that Ethiopia receives, grain will build up a crust on top if it is not covered. It is a common sight in some places to see grain piled up at harvest time, on a good crowned area so that water does not pool beneath the pile and spoil the grain. In Ethiopia it is a common practice to stomp down manure on the ground, which makes a very hard surface for seed cleaning and bagging areas. Various methods, such as these, could be employed to reduce as much spoilage as possible, until the grain can be stored in a more permanent location.

Long-term grain storage at the Alyssa farm will be provided by grain silos. They were shipped out of the United States in mid-June, and, once in Ethiopia, will then be trucked straight to the building site at the farm.

Grain Carts

Grain carts are needed for the harvest and planting on the Alyssa farm in Beltu. MAI employees originally looked into two different types of grain carts. Carts could be purchased and shipped from the United States or fabricated in Ethiopia.

The grain carts from the United States are capable of loading straight off of a combine by way of the attached auger. Grain can then be delivered off of the cart onto another truck or trailer by the auger. These carts are state-of-the-art. They have two large wheels and have a capacity to hold 850 bushels each.

The carts that can be fabricated in Ethiopia are side-delivery gravity carts with four wheels and weigh eleven tons each. These carts, of which MAI has the designs for, can hold 450 bushels each, or close to one dump truck load. When used in planting, side-delivery carts are ideal to deliver seed or fertilizer out on the field. However, grain from these carts cannot be directly unloaded onto a truck; it must be delivered into a ground pit or an air drill hopper.

From the two grain cart options available to MAI, it was decided to purchase grain carts in the United States rather than have them fabricated in Ethiopia. They are currently on a ship destined for Ethiopia.

On a farm, grain carts are typically pulled behind a tractor to be transported from place to place. The road system at the Alyssa farm will need some improvements to make the transportation of these grain carts easier. Ravines crossing the property could be difficult to cross, as well, with out some work done in the area.

Truck Fleet

At the furthest point from the Alyssa farm main headquarters, the property extends out fourteen kilometers. If driving along the perimeter road, rather than the center road, it is a 40 kilometer drive loop. This could cause a lot of wear and tear on tractors. The alternative is to purchase trucks for use on the farm; they could be purchased in the United States or outsourced in Ethiopia.

MAI is currently making the steps to move forward in this direction and obtain a truck fleet for company use.

Several options are also being investigated for the transportation of MAI people and goods within the country.

Kokosa

There are several projects ongoing on the MAI farm in Kokosa, while a few have been put on hold for the time being.

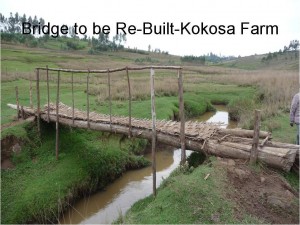

Bridge

Bridge

MAI would like to build a bridge to the village, but there are currently some issues regarding property boundaries between the farm and the local Ethiopians. This problem needs to be resolved before the bridge can be built. Adequate construction materials have been located in Addis Ababa, and they are ready for use once the bridge construction can begin.

Slaughterhouse & Dairy Facilities

Several options for the construction of slaughterhouse and dairy facilities in Kokosa are being considered. MAI employees toured a few local Ethiopian slaughterhouse facilities, in order to get an idea of the production capabilities of the local companies. One of these slaughterhouses was in Mojo, Ethiopia, and it was constructed by one of the companies that MAI is currently working with for construction in Kokosa.

The preliminary engineering, drawings, and analysis for the facilities to be built in Kokosa have been completed.

Arsi Negele Foresight Fathers Project

Arsi Negele Foresight Fathers Project

Morrell Agro Industries is working in conjunction with the Foresight Fathers in Ethiopia on various projects within the company.

The Foresight Fathers are helping out, when possible, with the MAI projects ongoing in Arsi Negele. The project has been inspected, and an engineer created the preliminary engineering and drawings. The buildings will be constructed using Hydra-Form blocks. The preliminary planning and engineering, which are necessary to construct the proposed buildings and facilities at the site, have now been completed. Joe Morrell has also been helping with the preliminary planning and engineering on these Foresight Fathers projects.

Dan Lager is currently analyzing what it would take to get local construction workers to help with the project, as well.